The thermographic cameras are valuable resources for predictive maintenance, helping industries in all segments to detect potential problems early in their manufacturing facilities.

Thus, it is possible to assist in the inspection of electrical, mechanical, structural and quality systems within an industrial installation. This avoids unscheduled downtime and the consequent drop in production. In addition, performance becomes safer and more efficient on the factory floor.

Thus, the main applications of thermal imaging Sydney cameras are predictive inspections and maintenance. Therefore, they take place in different areas of the industry, such as:

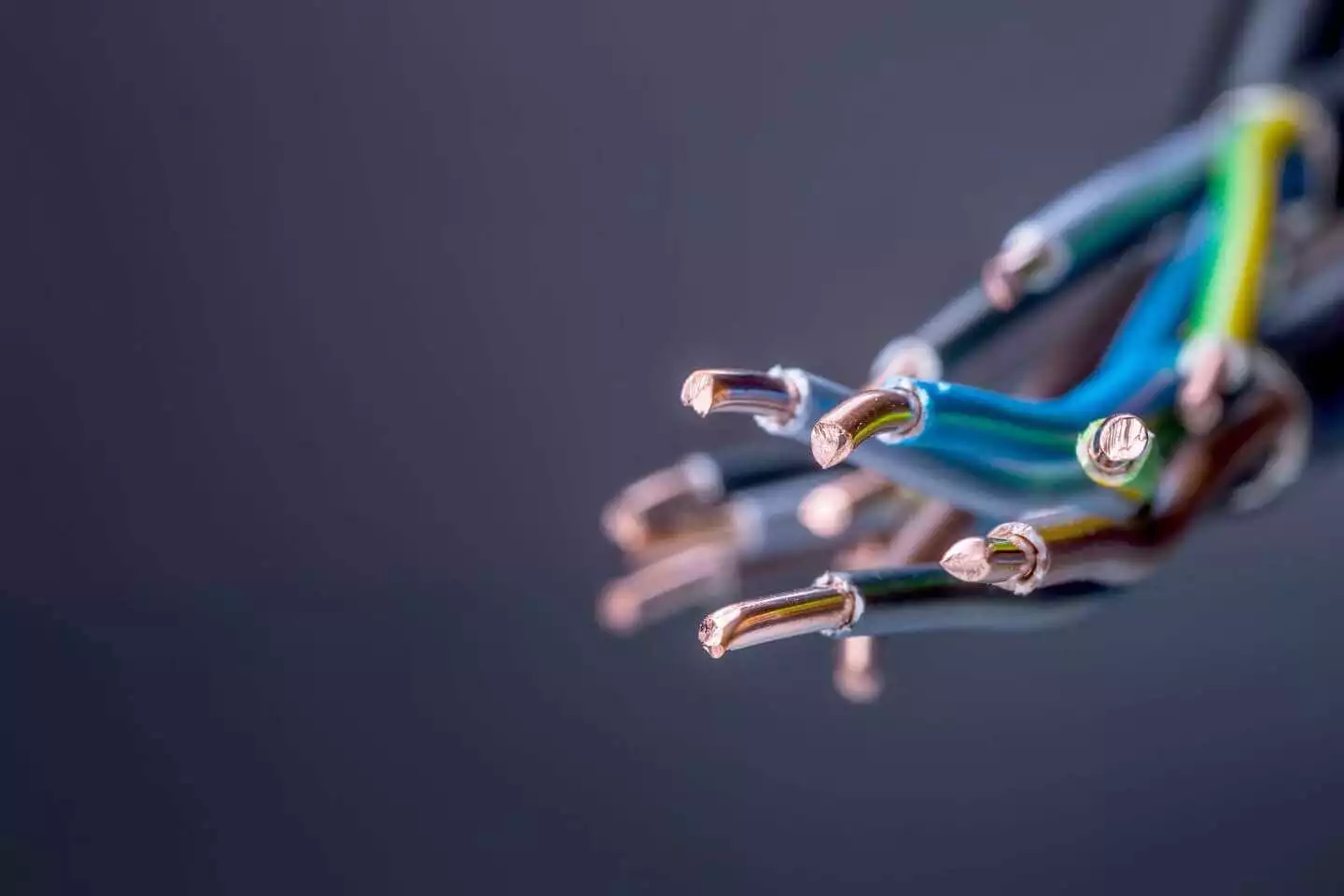

– Electrical systems: switchboards, connections, cables, transformers, primary cabins and substations.

– Mechanical systems: motors, pulleys, reducers, conveyor belts and all rotating systems.

– Heating / cooling systems: air conditioning units, heaters and heat exchangers.

– Manufacturing quality: thermal monitoring and vision systems.

– Detection of fugitive emissions: special thermographic cameras allow inspection to detect leakage of flammable and toxic gases.

– Fire monitoring: prevention of fire in fuel yards, waste piles, stock of raw materials and finished products and materials in general that offer a potential risk of spontaneous combustion.

Food industry examples

In the food industry, for example, thermographic cameras help control the temperature of perishable products. This happens during the entire storage, transportation, production and sales process.

In this context, with the use of cameras, it is possible to perform automatic non-contact measurements of temperature in several food processing places. In other words, it opens up the possibility of foreseeing quality problems that can lead to diseases caused by contaminated food. Thus, the control becomes more rigid.

The early detection of potential problems is, in fact, one of the great benefits of thermography. With the advance information brought by the thermographic cameras, it is possible to prevent system failures. With that, decisions can be based on accurate data and trends.